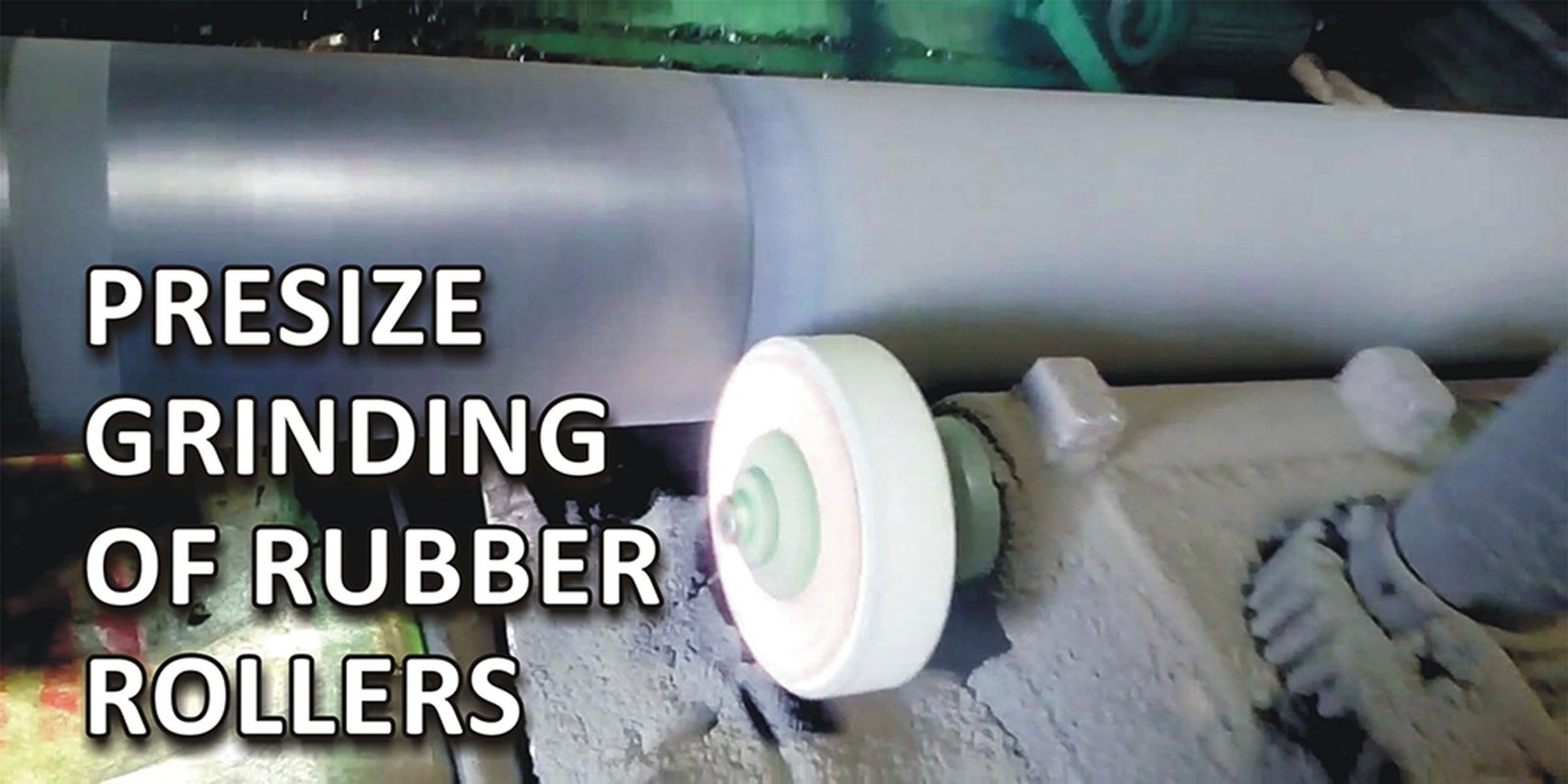

Presize Grinding of Rubber Rollers

For Textile & Paper Industries etc......

- 100% size guaranty

- Enhance the rollers rubber life

- Avoid the raptly Re Rubberization of Rollers

- Increase the Productivity

- Reduce the maintenance cost

Making A Visible Difference

We Serve You Batter Affordable Prices

Grinding of Rollers Ordinary way (with Lathe Machine)

- Waste the Rubber of Rollers by means of tools emery papers

- Prepare the uneven surface of Rubber Rollers

- Repeatedly Rubberization of rollers required

- Enhance the Maintenance cost

Antifoaming agents in food

The anti-foaming agents in food have the characters of good anti foamability, less quantity to be used, and it also can increase the whiteness and Exquisite feeling of the soybean product.

Main Composition

Polydimethylsiloxanes and its emulsion ,calcium carbonate

Application Scope and Characteristics

According to the principle of the foam generated in the process of soybean product, we finely make the high efficient defoamer using varieties of newest technologies and many kinds of food additives. The product has the characters of good anti foamability, less quantity to be used, and it also can increase the whiteness and Exquisite feeling of the soybean product. and increasing the product output and without aflatoxin and another toxic component meanwhile. to meet the requirements of physiological hygiene, it also can be used expansively in milk production, vinification, food processing, jelly sugar making, etc.

Using Method

Under the condition of stirring, when the temperature reaches 60-90?,to add the product at the proportion of 0.1—0.3% of the dry soybean amount. The best result will be achieved after the product and soybean milk foam flowing, mixed and dissolved together.

Food grade Defoamer

This food grade Defoamer is mixed evenly with water and foam fluid then adding in Foam fluid. It can be also added in the foam fluid directly.

Chemical Composition

Deionized water?Polydimethylsiloxanes? Food-grade emulsifier? Food-grade thickener

Method for Application

This food grade defoamer is mixed evenly with water and foam fluid then adding in Foam fluid. It can be also added in the foam fluid directly .The suitable dosage in common conditions is 0.01‰-1‰ of the total formulation weight, and dependent on the specific case of customer. The defoamer dilution should be used as quickly as possible.

Method for Application

Disinfected with bass raw materials, it also can be disinfected partly by adding material in the later part of the fermentation process. In general, under normal conditions, the dosage of 0.1-5‰ will meet the requirement. of fermentation defoaming cycle.

Mineral Oil Antifoam/Defoamer for Water-Based Paint and Ink

Mineral Oil Antifoam/Defoamer, which does not contain silicone components, is used in the polymerization, coagulation and degassing processes of the rubber and plastics industry. It can eliminate foam generated by the action of various surfactants in the system. In addition, it can also be used in resin products, water-based paints, latex paints, water-based inks, emulsion polymerization, polymer adhesives, styrene-acrylic emulsions, papermaking, petrochemical industry and all industries where silicone defoamers are not suitable.

Main Characteristic:

- It consists of mineral oil, fatty acid metal soap and dispersant;

- It has little effect on the coating/painting film and with high efficiency;

- Particularly suitable for aqueous ink systems;

Application:

- Water-Based Paint and Ink

- Water-based architectural coatings for high, medium and low PVC;

- Other polymer systems that cannot use silicone;

How to use

- Antifoam control agent is composed of a variety of substances, which may be stratified or precipitated during storage, which is normal. It is recommended that the user stir slightly before use, without affecting the use effect.

- Antifoams can not be diluted with water, but can be added directly to the foaming system. If diluted with water, stratification may occur, which will reduce the effect of defoaming and will eventually lead to an increase in the cost of use.

- Because defoamer has strong antifoaming properties, it can be added to the product as a foam suppressing component. The recommended addition amount is 0.1~0.5% of the total formula amount. It can also be added in stages. Add 40% of the mass in the grinding stage, and add the remaining 60% in the paint adjustment stage (before adding the emulsion). The optimum amount is determined by the user through field trials.

Antifoam agents used in fermentation Series polyether defoamer for Industrial fermentation

The Antifoam agents used in fermentation Series polyether defoamer for Industrial fermentation is mainly designed for fermentation defoaming industry, with the characteristic of quick defoaming and long time foam depressing effect. It also can be easily dispersed in water,and has good compatibility with liquid , non-toxic, non-corrosive.

1. Usage and characteristics

The product is mainly designed for fermentation defoaming industry, with the characteristic of quick defoaming and long time foam depressing effect. It also can be easily dispersed in water,and has good compatibility with liquid , non-toxic, non-corrosive. It is mainly used in the fermentation procedure of citric acid? oxytertracycline? penicillin? Tetracycline? aureomycin?lincomycin? erythrocin? neomycin? aminoglutaric acid? diaminocaproic acid? Abamectin,enzyme reparation?coenzyme-Q10?erythritol?yeast? xanthan gum? Long-chain dicarboxylic acid. It also can be added to the manufacturing process of other chemicals.

2. Method for Application

Disinfected with bass raw materials, it also can be disinfected partly by adding material in the later part of the fermentation process. In general, under normal conditions, the dosage of 0.3-1.0‰ will meet the requirement of fermentation defoaming cycle

Industrial grade solid defoamer powder antifoam for cement self-leveling/ cement mortar

Powder antifoam/defoamer is mainly designed for the foaming characteristics of cement mortar mixing process. The use of cement mortar defoamer can effectively control the foam generation in the cement mortar system, making the concrete components more dense and bright. It helps the combination of the carrier and the foaming system, is easy to disperse into the foaming system, and combines the two, has a low surface tension, contributes to the suppression of foaming, and can reduce the cost.

Product Description

Industrial grade solid defoamer powder antifoam for concrete admixture defoaming agent of cement self-leveling/ cement mortar/powder gypsum plaster.

Main Composition:

a) Liquid hydrocarbon, hydrophobic particles;

b) It is especially suitable for defoaming of cement self-leveling, cement mortar and cement concrete admixture;

Superior Properties and Advantages

Powder antifoam/defoamer is mainly designed for the foaming characteristics of cement mortar mixing process. The use of cement mortar defoamer can effectively control the foam generation in the cement mortar system, making the concrete components more dense and bright. It helps the combination of the carrier and the foaming system, is easy to disperse into the foaming system, and combines the two, has a low surface tension, contributes to the suppression of foaming, and can reduce the cost.

1. Fast Defoaming speed, long foam suppression time, high temperature resistance and

strong alkali resistance

2, good dispersion in cement mortar system, does not affect product firmness

3, does not affect the product’s water reduction rate, does not affect product quality

4, very strong stability, especially suitable for defoaming and foam suppression under

alkaline conditions

5. Low dosage and high efficiency.

6. Increase the strength and brightness of concrete members

7. This product is non-toxic and odorless, which is conducive to production safety

How to use

1. The recommended use of is to add water to the concrete after mixing with the additive.

The addition of it will reduce the bubbles in the system.

2. The defoamer has a flowing property and is well-matched with the powder

coating. Suitable for caulking agent, interior and exterior wall putty, with certain versatility

Application

1. Defoamer for concrete admixture

2. Antifoam agent for cement self-leveling,

3. Defoaming agent for cement mortar and cement concrete

4. Defoamer for powder gypsum plaster

5. Antifoam agent for Interior and exterior wall putty, caulking agent, gypsum prefabricated board

Defoamer manufacturers dimethyl silicone antifoams for metal cleaning

Dimethyl silicone antifoams should be diluted with water or foam liquid into even ingredient then added into foam liquid,also can be added directly. The suitable dosage is dependent on the specific case of customer. The defoamer dilution agent should be used within 6 hours.

Defoamer manufacturers dimethyl silicone antifoams for metal cleaning

Focus on research, business and production of various chemical organic silicone products for 24 years!

Polydimethylsiloxane emulsion silicone food grade antifoams

Application scope and characteristics

According to the principle of the foam generated in the process of soybean product . we finely make the high efficient defoamer using varieties of newest technologies and many kinds of food additives. The product has the characters of good anti foam ability, less quantity to be used ,and it also can increase the whiteness and Exquisite feeling of the soybean product.and increasing the product output and without aflatoxin and another toxic component meanwhile.to meet the requirements of physiological hygiene, it also can be used expansively in milk production, vinification,food processing,jelly sugar making etc.

Using Method

Under the condition of stirring,when the temperature reaches 60-90?,to add the product at the proportion of 0.1-0.3% of the dry soybean amount .The best result will be achieved after the product and soybean milk foam flowing, mixed and dissolved together.

Polydimethylsiloxane emulsion silicone food grade antifoams

Polydimethylsiloxane emulsion silicone food grade antifoams is used in the food processing industry to solve the problem of a large amount of foam in the production process-tofu, soy milk (all soybean products are processed), potato starch, fruit juice, dairy products, soy protein extraction, edible oil, sugar, hot pot seasoning, etc.

Product Description

Focus on research, business and production of various chemical organic silicone products for 24 years!

Polydimethylsiloxane emulsion silicone food grade antifoams

Application scope and characteristics

According to the principle of the foam generated in the process of soybean product . we finely make the high efficient defoamer using varieties of newest technologies and many kinds of food additives. The product has the characters of good anti foam ability, less quantity to be used ,and it also can increase the whiteness and Exquisite feeling of the soybean product.and increasing the product output and without aflatoxin and another toxic component meanwhile.to meet the requirements of physiological hygiene, it also can be used expansively in milk production, vinification,food processing,jelly sugar making etc.

Using Method

Under the condition of stirring,when the temperature reaches 60-90?,to add the product at the proportion of 0.1-0.3% of the dry soybean amount .The best result will be achieved after the product and soybean milk foam flowing, mixed and dissolved together.

Defoamer manufacturers dimethyl silicone antifoams for metal cleaning

Dimethyl silicone antifoams should be diluted with water or foam liquid into even ingredient then added into foam liquid,also can be added directly. The suitable dosage is dependent on the specific case of customer. The defoamer dilution agent should be used within 6 hours.

Defoamer manufacturers dimethyl silicone antifoams for metal cleaning

Chemical Composition: Polyorganosiloxanes Nonionic-emulsifier Dispersant The product is mainly used in sewage treatment, metal cleaning and so on, with characteristics of quick defoaming, non-toxic, odourless, and will not bring secondary pollution.

Under the condition of stirring,when the temperature reaches 60-90?,to add the product at the proportion of 0.1-0.3% of the dry soybean amount .The best result will be achieved after the product and soybean milk foam flowing, mixed and dissolved together.